Our Product

Product

Tell us what you need

we’re very professional supplier in timing pulleys, gears, worm gear, bearings,couplings,some motion and transmission parts.All products are manufactured strictly in accordance with the international standards (ISO).The products are widely used in CNC machine,3D printer,automobile,textile machine,agriculture machine,construction machine,automatic apparatus and well sold both in domestic and abroad.

Our future development is based on this knowledge,the human resource,and our commitment to development principles.

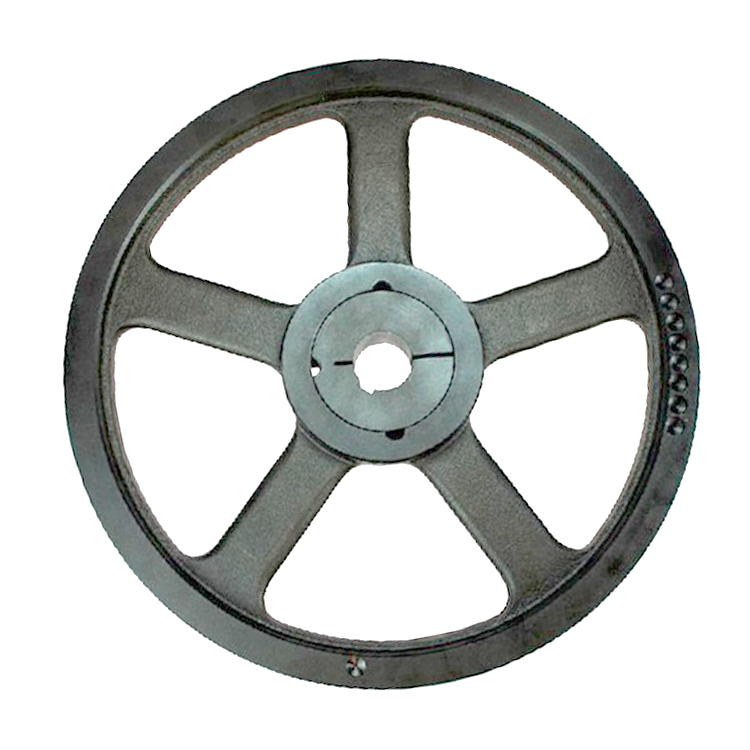

Metal Pulley Wheel

Surface treatment Sand blasting, polishing, Anodize, zinc/nickel/chrome/ plating,

Power coating, passivation,Heat treatment, etc.

pulley wheel for agricultural

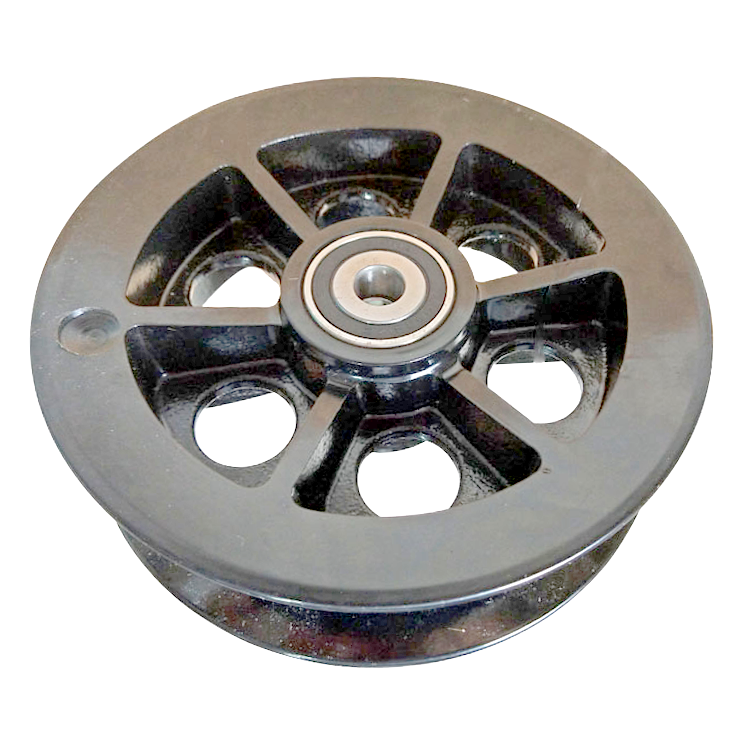

pulley wheels are one of the specialty products that we manufacture in our in-house machine shop that is well-equipped with sophisticated machinery.

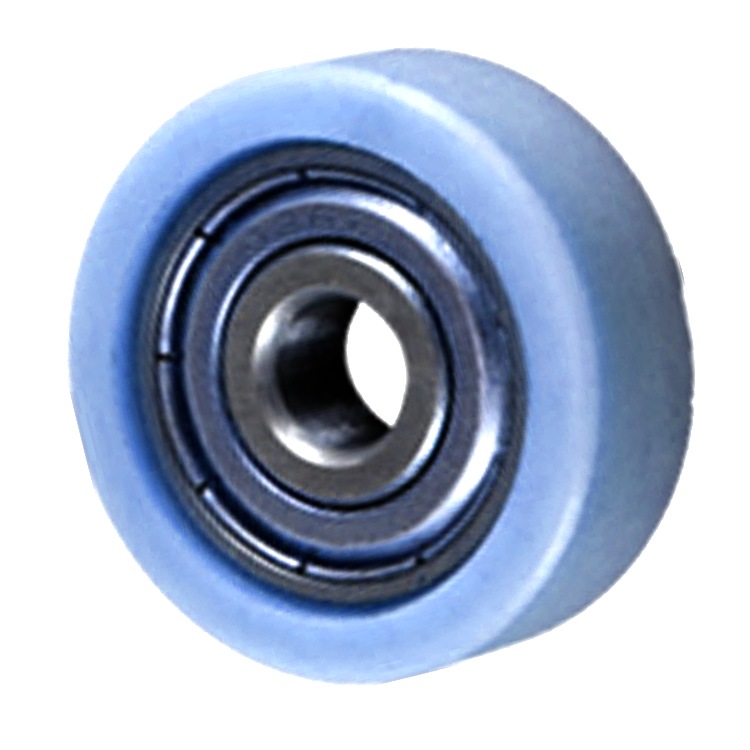

nylon pulley wheels

Our custom polyurethane pulley wheels are made from tough, premium grade urethane, as such provide reliable performance and are the absolute solution for high-stress applications.

Wire Drawing by Pulley Wheels

We can machine wheels for ferrous and non-ferrous applications. Ferrous materials such as cast iron and steel can be heat treated or flame hardened as needed.

rope wire belt pulley wheel

The plastics industry is responsible for introducing many synthetic materials that are used today on a wide variety of machines and systems.

V Belt Pulley Wheel

Precision zinc alloy sheaves feature machined grooves and bores for high concentricity and offer your choice of spoked and solid construction.

cable wire pulley wheel

Wire rope blocks and sheaves from Grainger help lift heavy loads. Use them with heavy-duty wire rope and aircraft cable in high-load and medium-speed applications.

iron casting pulley wheel

A pulley is a wheel on an axle or shaft that is designed to support movement and change of direction of a taut cable or belt, or transfer of power between the shaft and cable or belt.

timing pulleys wheels

The numerical control lathe completes each process, and the comprehensive inspection tool detects the shape of the concave mold, and the dynamic balance is completed by the dynamic balance machine .